“If your alternator needs rebuilt, why not do it yourself, add 50 amps to the power AND save big $.”

Many people have the wrong impression about what causes the amperage output of an alternator.

It’s not actually done by electronics or some type of adjustment. We increase the amperage output by giving you a high amp stator and rectifier (already soldered together). This is the major component in the alternator itself. Our kits however, because of our years experience in the alternator business, find the sweet spot. Now, you can rebuild your own alternator, significantly increase the output of your alternator, AND save a lot of money. ALL AT THE SAME TIME.

“Need your alternator  rebuilt? We show you how to”

rebuilt? We show you how to”

- Get the core (minimum down time).

- Rebuild your own with exact how to video.

- Crank up the amps with our high quality kits.

- We supply any support and warranty you need.

As we all know, the technology advancements in the automotive industry fo r the last 2 decades have been astoundingly fast paced. Electrical demands on the charging system are no longer an option, but a requirement. Millions of customers need to further the electrical system stress, due to aftermarket add ons such as safety and roadside assistance vehicles, specialized work vehicles with winches, lights and welding or compressor equipment.

r the last 2 decades have been astoundingly fast paced. Electrical demands on the charging system are no longer an option, but a requirement. Millions of customers need to further the electrical system stress, due to aftermarket add ons such as safety and roadside assistance vehicles, specialized work vehicles with winches, lights and welding or compressor equipment.

Hob byist and extra curricular aftermarket add ons to vehicles have become a necessity in today’s society. The need for personal stress relief from the grind is no longer a preference, but a right of passage. The demand for vehicles that serve dual purpose (both transportation and entertainment) is ever more popular in a stressed economy. Just ask a teenager about his car and wait for the “sound system” to be mentioned first.

byist and extra curricular aftermarket add ons to vehicles have become a necessity in today’s society. The need for personal stress relief from the grind is no longer a preference, but a right of passage. The demand for vehicles that serve dual purpose (both transportation and entertainment) is ever more popular in a stressed economy. Just ask a teenager about his car and wait for the “sound system” to be mentioned first.

Here are the basic categories or reasons for an alternator upgrade.

This is probably the most popular reason in the automotive market for a high amp alternator upgrade. Do your headlights go dim when the bass thumps on your stereo? This is a common problem. Our upgrade kits are recommended for 1500 watts and under. There are a few things that can also be done to enhance the performance of the average sound system.

- Adding on an extra battery can be a huge improvement to the overall performance of a stereo system. Not only does the extra battery act as a capacitor to absorb power surges from the amplifiers, but it allows for extra amperage output which relieves stress on the rest of the system.

Extra batteries can be located in the engine compartment, or in the trunk, where ever you choose. Just run heavy duty cables + to + and – to -. We do NOT recommend the use of a battery splitter (isolator). We also do NOT recommend using the vehicle frame or unibody structure in place of a full sized ground cable.

- The use of audio quality capacitors : This will extend life expectancy of all components AND improve overall audio quality and electrical performance. There are commonly referred to as “caps” and are available anywhere from Walmart to your local professional audio distributor. Your choice of quality and performance of capacitors is highly dependent on budget.

- Installation of a trickle charger (float charger) to plug in to AC when system is resting.

Some systems will undoubtedly tax or over abuse the vehicle electrical system. Depending on the length of time the system was used, or the volume of the system’s duration, batteries can be depleted 50% or more without the operator’s knowledge. Even a 10% depletion of battery charge can be compounded by the next duty cycle.

The answer is to install a trickle charger. This the best way to bring batteries back to a full state of charge is a slow ½ -1 amp charge over night. A fast charge of 10 amps or more is not as effective and can boil off acid. Try to buy a smart charger that will not overcharge batteries if left alone for extended periods of time. 15VDC as a cut off point would be ideal. Wire tie down the wires and the body of the charger to dampen vibration. Mount the charger where an optimum amount of air for cooling purposes is available. Run the AC plug through a grill or other access point, so an extension cord can be easily plugged in when the vehicle is at rest. Try to mount the unit on the coolest surface available like a firewall or inner fender. Read More

The off road vehicle market is the another extremely popular candidate for alternator hi amperage upgrade. Continuous above average illumination for night time usage is essential and is a constant drain on an electrical system. Many times the amperage discharge period is during vehicle engine off times or low RPM when an alternator is at it’s lowest amp output.

The off road vehicle market is the another extremely popular candidate for alternator hi amperage upgrade. Continuous above average illumination for night time usage is essential and is a constant drain on an electrical system. Many times the amperage discharge period is during vehicle engine off times or low RPM when an alternator is at it’s lowest amp output.

Many specialized vehicles across the US are mainly intended for roadside assistance for stranded motorists. This category includes emergency repair vehicles for automotive, truck and mobile tire service vehicles. As always, safety from passer by vehicles traveling at high speeds is paramount.Many of these vehicles require high output work lighting, as well as safety light bars on the top of the vehicle. The extra power needed to equip these vehicles can easily overcome the alternator amperage output that was supplied by the original equipment manufacturer. Read More

SPECIALIZED WORK VEHICLES (SNOW PLOWS)

Possibly no other vehicle on the road today is more abused than the snow plow equipped truck.Work lights, extra safety marker lights, electrically taxing hydraulic systems, and salt spreaders are among the basics for these continuous duty when needed operations. Just the exposure to salt alone is enough to wreak havoc to all metallurgy in the nearby area. Alternators are no exception, if not possibly even more vulnerable than most other nearby components. Read More

TOWING VEHICLES (TRAILER HAULING)

Vehicles intended for towing and recovery are basically the same electrical loads and demands as roadside assistance vehicles. Extra power for additional marker lights, work lights and safety light bars is considered an absolute requirement. Tow trucks often arrive at the scene to find the distressed vehicle is suffering from a dead or completely depleted battery. Even with the market flooded with the ever popular jump boxes, the eventual occasional occurrence of a set of jumper cables from the tow truck to the distressed vehicle is practically inevitable.

This scenario of jumper vehicle / jumpee vehicle is an enigma in itself, requiring exceedingly additional amperage from the tow truck alternator. Extreme power surges can be avoided by shutting off the tow truck and allowing the alternator to stop rotating BEFORE removing the jumper cables from the batteries. Read More

What exactly makes an alternator into a hi amp? (How we do it)

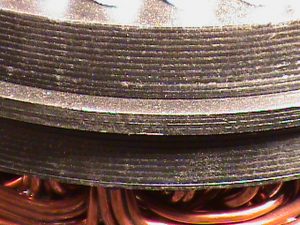

Amperage is a factor that is engineered from the beginning of the manufacturing process. It is relevant to the size and winding style of the copper wire, and the size and weight of the other raw material in the stator which is the metal lamination stacks. The rotor consists of a long copper wire arranged as a coil. The coil surrounds a solid metal core. The size and weight of the core, and the size and length of the copper wire in the coil is also a determining factor for amperage output.

the size and winding style of the copper wire, and the size and weight of the other raw material in the stator which is the metal lamination stacks. The rotor consists of a long copper wire arranged as a coil. The coil surrounds a solid metal core. The size and weight of the core, and the size and length of the copper wire in the coil is also a determining factor for amperage output.

Generally, the stator and rotor are a matched set and it is not recommended to mix and match the set out of engineered design because there are other factors designed into the windings like RPM cut in. It would also be considered a bad thing to install a low amp stator with a high amp rotor because the stator will overheat and fail very prematurely.

However, what CAN be done, is you can install a higher amp stator on an existing rotor. The result is a desirable amp increase (40-50 amps DC). It  would add an average of 30%-40% to the overall strength of the charging system which allows a much quicker recovery time for the battery to recharge. This also provides a much stabler environment for voltage to maintain availability to loads.

would add an average of 30%-40% to the overall strength of the charging system which allows a much quicker recovery time for the battery to recharge. This also provides a much stabler environment for voltage to maintain availability to loads.

40-50 amps is a moderate increase in overall charging system efficiency. The great thing about a moderate change is that you don’t have to beef up the wiring or add another battery if you don’t want to. The more amps you get to your stereo, the better it’s going to sound. Then the stereo (under 2000 watts) will stop robbing power for the headlights or the engine.

Low RPM output.

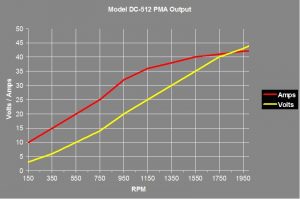

The biggest advantage is the strength a higher amp alternator adds to the system at low RPM. Periods of low RPM is when the stock alternator is at it’s weakest output, as you can see by a typical alternator at the left. All the charging data on all alternators are at the most minimal wattage output during low RPM. Unfortunately, the loads like hi output stereo equipment, AC and rear defog do not demand less amps at lower RPM’s. The vehicle will switch to running off the battery when sitting at a traffic light with a heavy electrical load.

The biggest advantage is the strength a higher amp alternator adds to the system at low RPM. Periods of low RPM is when the stock alternator is at it’s weakest output, as you can see by a typical alternator at the left. All the charging data on all alternators are at the most minimal wattage output during low RPM. Unfortunately, the loads like hi output stereo equipment, AC and rear defog do not demand less amps at lower RPM’s. The vehicle will switch to running off the battery when sitting at a traffic light with a heavy electrical load.

This is where the higher output alternator is at it’s biggest advantage. It not only charges more at higher RPM’s, but it also charges more at lower RPM’s which is where it is most needed. It also will run cooler than a stock alternator at most given amperage and RPM’s. This is also a huge advantage because copper becomes less and less efficient as it’s temperature increases.

An inefficient charging system can also be known to decrease battery life expectancy. Wet cell batteries loose life expectancy from being discharged too often or too much. Additionally, this will have a negative effect on the alternator during warm up time because the battery may be less than specific gravity (12.6VDC) and continually stress the voltage regulator.

Can my alt be tweaked to go higher?

Technically the scientific answer is “No” you can’t tweak an alternator into putting out more amperage. But, we can show you how to make it work much more efficiently. As we explained in the previous article, amps is an engineered product of the manufacturer. But, this is a great opportunity to install a rebuild kit to insure reliability and maximum performance. If the brushes, diodes or voltage regulator are worn or ready to soon fail, this will affect the overall output of the alternator, so that it may not even be performing to the intended factory spec’s.

For example, say you have a pair of old, partially worn brushes. A stereotypical alternator with a 5 amp field current and a typical 110 amp total output. So this means the alternator achieves a total of 110 amps current output when the voltage regulator allows 5 field current amps to flow through the rotor. But the brushes are part of the field circuit. The smaller the current driver, the more problems it will have with conductivity without resistance.

In other words, the more problems it will have due to partial wear and dirt or pollutants like oil and antifreeze. So, if the field current cannot achieve 5 ADC, the alternator will not charge at full capacity. Compounded charging system loss will significantly occur proportionally at lower RPM’s.

Naturally, there is a lot to be said for the overall cleanliness of connections with the application of dielectric or hi temp white lithium grease. This can be applied to numerous areas inside the alternator as per specific instructions in our Rebuilder in a Box how to video. This procedure is also recommended (as we all know) to the wire terminals and plug connections outside the alternator.

But, what many people forget is the ground side of the circuit. We all know how important the grounds are on a vehicle. Be sure to sand or buff the areas where the case of the alternator or starter contact the block. Also the under side of the heads of the bolts, and the threads of the bolts should be cleaned with a buffing wheel. Be sure to apply white lithium or dielectric grease to all areas cleaned. Oxidation can begin to occur in as little as 24hrs.

Don’t forget that brackets that the alternator mounts to can be dis assembled and sanded and lith greased where they bolt to the engine block itself.

What else can I do for a stronger system?

Adding another battery to strengthen a charging system is a great way to pack some extra punch. This works out great for snow plows because of the constant wear on the battery when plowing big jobs that need lighting. It also is highly recommended for stereo systems because it helps absorb transients and surges left over from the high powered bass thumps.

The batteries are hooked up parallel or + to + and – to – . This procedure will deliver twice the reserve capacity and twice the cold cranking amps. Also batteries have the ability to soak up a lot of noise in a high amp stereo system.

Vehicles with powerful aftermarket sound systems are constantly plagued with CEMF. Also known as counter electromotive force. It means that when a sudden power surge (like a bass thump) travels from the power amp to the speakers, it does not always get entirely used up by the speaker. The left over power is called a transient and can be very damaging to surrounding components because it dissipates to the entire electrical system, even an on board computer if it’s in it’s path.

The electronic solve for this scenario is the large capacitor. Capacitors act as a vacuum cleaner for the noise or dirt in a system caused by hi amp transient surges. But a heavy duty lead acid battery is a huge help. It will act as an oversize organic dampener when exposed to surges that occur at a broad band frequency allowing the caps to work more efficiently.

The electronic solve for this scenario is the large capacitor. Capacitors act as a vacuum cleaner for the noise or dirt in a system caused by hi amp transient surges. But a heavy duty lead acid battery is a huge help. It will act as an oversize organic dampener when exposed to surges that occur at a broad band frequency allowing the caps to work more efficiently.

This is why 2 batteries is better than one in a hi output stereo system. The extra battery provides 2 times the cushion to help out the caps. We do not recommend the use of a battery isolator for a stereo high amp application. Isolators used for these vehicles tend to cause a lot of problems, without providing any real benefit other than saving an absent minded driver. Isolators have one beneficial purpose: If a user turns his vehicle off and listens to the stereo, it will prevent 2 dead  batteries when the user may be too stupid to turn his car back on to let the batteries charge up. Isolators would have more consideration to be designed beneficially into an electrical system for motor homes or limos.

batteries when the user may be too stupid to turn his car back on to let the batteries charge up. Isolators would have more consideration to be designed beneficially into an electrical system for motor homes or limos.

Braided ground straps are also a great way to help clean up noise in a system. This will help the voltage regulator to function better because of a clean environment. Straps can be installed from negative battery terminals to a body ground. The extreme stereo enthusiast can get really crazy with this area. Hoods and doors can act as collectors or resonators, and transmit noise into the system by induction. To cure this a braided wire cable is installed from the doors to chassis and from the hood to the chassis. This practice contains a 2 fold benefit. The high output audio system will have less noise and the alternator will perform better.

AB both switch verses isolator.

This portion of the article is intended mainly for motor homes, boats, recreational vehicles and limos. Although a small percentage of automotive may be interested, it is not commonplace to park a car and run various electrical loads for long periods of time like it is on RV’s, motorhomes, boats, and occasionally a limo. It is commonplace for these vehicles to park for long periods of time, and still continue to run various electrical loads without restarting the engine to recharge the batteries. A dead battery is inevitable. This is why multi battery systems with isolators or A-B-Both switches were invented.

The purpose of a battery isolator is to electronically select one battery or the other to drain. When the battery is completely dead, the loads will shut off. That way, there is still one battery that is fully charged for restarting the vehicle. This can really save you in a remote location if you forget to turn off loads or fall asleep with loads on. The down side of battery isolators is unless you spend a bundle on them, they are very prone to failure, dysfunction, and are relatively well known for placing an undue amount of stress on the alternator. Also the diodes in an isolator will cause an undesirable slight voltage drop.

There is one other financially logical fact to consider : An emergency jump box can be purchased for roughly the same cost as a battery isolator and it won’t interfere with the amperage flow or cause mal function problems at a later time.

This is why we generally recommend a manually operated A-B-Both switch with individual volt meters on each bank of batteries. This is a much more efficient and trouble free approach to the problem as long as the user exercises these 3 common sense rules.

- Switch to B when parking vehicle

- Switch to A when starting vehicle

- Switch to Both to recharge with alternator or hook up charger to recharge B battery (ies).

The B battery can be several or a group of batteries, or even deep cycle batteries depending on the accessories and the amount they drain on average usage. We recommend a 2 voltmeter set up. One for the A battery(s) and one for the B battery(s), so that voltage can be independently observed at any time. Normally deep cycle batteries are not recommended as a stand alone with an automotive type voltage regulator. As a matter of fact, just a single deep cycle battery in an automotive charging system is a recipe for disaster. But after years of observation : When deep cycle batteries are recharged in parallel with regular lead acid batteries, everything seems to work out fine. This makes an ideal setup for motor homes and RVs, particularly if the shoreline (AC hookup) incorporates a battery charger.

The B battery can be several or a group of batteries, or even deep cycle batteries depending on the accessories and the amount they drain on average usage. We recommend a 2 voltmeter set up. One for the A battery(s) and one for the B battery(s), so that voltage can be independently observed at any time. Normally deep cycle batteries are not recommended as a stand alone with an automotive type voltage regulator. As a matter of fact, just a single deep cycle battery in an automotive charging system is a recipe for disaster. But after years of observation : When deep cycle batteries are recharged in parallel with regular lead acid batteries, everything seems to work out fine. This makes an ideal setup for motor homes and RVs, particularly if the shoreline (AC hookup) incorporates a battery charger.

How do I know if I should have a stronger alternator.

Many authors have published various methods of adding the amperage loads in a given electrical system. There are charts that estimate the amperage draw of stereotypical accessories and compare them as a total, to the output of the alternator. Also some authors estimate a particular load by observing the fuse that protects the accessory, totaling them together and allowing 15% leeway for the alternator amps output.

The following is an easy yet precise test for rating the charging system (alternator, battery and wiring as a whole) on a scale of 1-10. Battery(s) must be trouble free and as best as the driver knows at a full state of charge.

- Wear safety goggles.

- Start vehicle in park. Let idle.

- Turn on loads, wait exactly 5 min.

- Observe VDC with a digital volt meter.

13.0 VDC=10

12.9 VDC=9

12.8 VDC=8

12.7=7

12.6=5-6

12.5=4

12.3=3

12.0=2

UNDER 11.0VDC =1

If voltage continues to drop quickly= 0

This is a test of your specific vehicle entire charging system’s ability to maintain the loads it has. Compound resistance in the wiring and alternator, due to age and wear and tear are organically compensated for. This is not necessarily a test, just for the alternator. Battery reserve capacity which is rated in amp hours is also a huge factor, as can be proven by getting a heavier duty battery or parallel 2 batteries together and perform the test again. Also, the test can be performed again (after the battery has been recharged) with various loads omitted so that the driver has the option of knowing what causes the most drain on the system.

To determine if a bigger battery would improve the charging system, obtain a set of heavy duty jumper cables, and the biggest, heaviest lead acid battery you can temporarily borrow. You can even jump from another car but the car has to not be running for 15 min prior to test. With a set of heavy duty jumper cables, parallel to the test vehicle like you were jumping it. The auxiliary car should be off, or just a plain battery sitting on the ground. (note : jump boxes do not work well for this test). Start the test vehicle and re perform the test. If the results improve, you know a better battery would raise the test results. If it does not, there is a problem with the charging system.

“There are a few things that can be done as a test before installing a high amp alternator.”

A smaller pulley on the alternator will cause a higher amperage output at lower RPM’s. Also there may be a small voltage drop in the cable from the battery post output on the alternator to the positive battery post. An additional wire may be added on top of the existing cable rather inexpensively as a test. Usually about 3 feet of #10 wire with a ring terminal or alligator type connector on both ends will do nicely to see if the test results can be raised after installation. The wire goes from the output terminal on the alternator to the battery positive terminal.

If the desired charging system results are not achieved after these 3 factors (stronger battery, smaller pulley, better charge cable) have been actual test eliminated, you know that you need a stronger alternator to improve the charging system.

A little help can go a long way.

The best way to charge a battery is slowly at the lowest amp rating on your charger. As a metaphor : Charging a battery should be like filling a water bucket with soap in it. If you put the water in fast, it will fill up fast. But soon the bubbles will disappear and you’re left with an empty bucket. If you put the water in slowly, it will fill to the top and the job is efficiently completed. With this in mind, although the results are much slower, the best charger is a trickle charger.

Many work vehicles are exposed to ultimate duty on one day, then minor work schedule on the next day. The easiest fix to a wide scale variation in electrical loads is the installation of a under the hood trickle charger. Permanently fasten (or install a switch on the negative lead) the leads on the trickle charger to the battery system according to the manufacturer’s specifications. Then run the power supply cord through the grill in an inconspicuous spot.

If you think the batteries may be running low, plug in the charger when the vehicle is at rest. If you know that the vehicle was exposed to light electrical loads that day, skip the charging period that night. Be sure to check with the manufacturer’s specs to see if the charger will auto shut off if the battery voltage hits the designated high limit. You have to be careful not to overcharge the batteries and boil off electrolyte.

This is a highly recommended procedure for vehicles with extra curricular electrical loads.

The beauty is the low cost of many of the trickle chargers available at local big box stores verses the large benefit of beginning each work day with a fully charged battery. This equipment can extend battery and alternator life expectancy, as well as increase duty cycle time. This is also a very simple install with little or no hardware required. Of course the alligator style clips found on most battery chargers can be replaced with permanent installation ring terminals and hooked up to battery top posts or the manufacturer provided jump terminal and engine block ground.

Find out about HD reverse motors for tikes